SHENZHEN WANDA-AN PRECISION TECHNOLOGY CO.,LTD Info@szwandaancnc.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Material: Aluminum, Stainless Steel, carbon steel, Brass, etc

Process: Lathe turning, CNC turning, CNC milling, Wire cutting, Laser cutting, Drilling, Grinding, etc.

Finished by : Zinc plating, chrome plating, nickel plating for carbon steel parts, Passivating for stainless steel parts, Anodizing for Aluminum Parts, Painting, Powder coating, surface polishing…

Wanda-An Precision is a trusted CNC machining parts supplier from China. With an array of services and reliable quality assurance, our machined parts are ideal for manufacturing applications.

In the world of electronics, making secure and reliable connections between components is essential for the proper functioning of devices. One component that plays a critical role in ensuring such connections are made effectively is the PCB screw terminal.

PCB (Printed Circuit Board) screw terminals are essential components in many electrical devices, providing a secure and reliable way to connect wires to a PCB.

When designing or assembling an electronic circuit, choosing the right connection method for your components is crucial for ensuring performance, reliability, and ease of maintenance.

When designing and building electronic circuits, one of the most crucial decisions you'll make is how to connect components to the PCB (Printed Circuit Board). The two primary methods for making these connections are PCB screw terminals and soldered connections.

In the world of manufacturing, precision is key. Whether for aerospace, automotive, electronics, or fiber-optic communication industries, the ability to create intricate, high-quality components is a critical factor in success. Two primary methods for achieving these results are CNC machining and tr

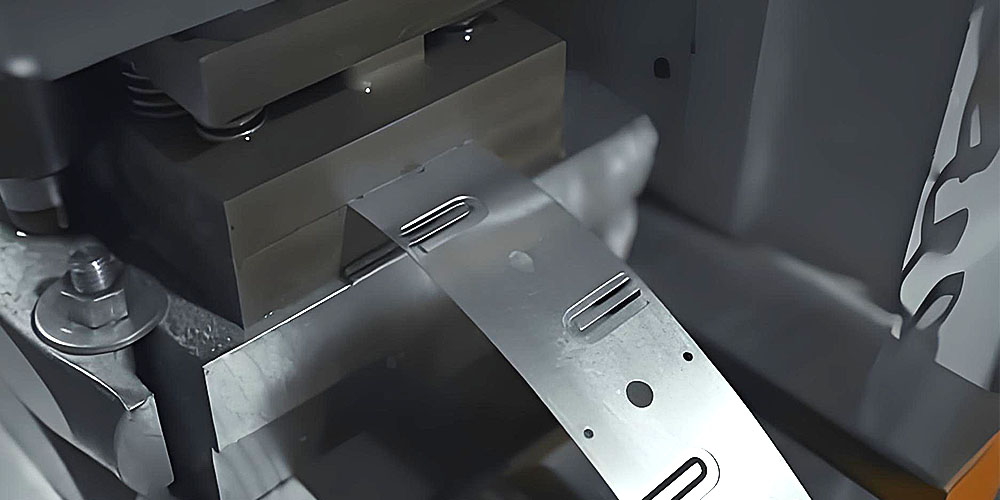

When it comes to manufacturing and production, the choice between Stamping Machining Service and laser cutting can significantly impact the quality, cost, and efficiency of your project. Both methods are widely used in various industries for metalworking, but which one is the best for your specific

In today's manufacturing landscape, stamping machining service has become a critical process for producing precision metal parts, with applications across numerous industries such as automotive, aerospace, electronics, and consumer goods. As technology evolves, the future of stamping machining promi

In today's manufacturing world, CNC machining plays a vital role in transforming raw materials into high-quality, precision-engineered products. From aerospace components to automotive parts and electronics, the CNC machining process ensures consistency, accuracy, and efficiency in production. As in

CNC (Computer Numerical Control) machining services are critical for industries that demand high precision and quality in their manufactured parts. Whether in aerospace, automotive, electronics, or any other industry, maintaining consistent precision is essential for ensuring that components meet th

IntroductionBattery holders are an essential component in the electrical equipment industry, ensuring that batteries are securely housed while providing reliable power to a variety of devices.

IntroductionIn the rapidly advancing Electrical Equipment Industry, precision and reliability are crucial for maintaining high performance and durability.

The electrical equipment industry is a cornerstone of modern technology, powering everything from household appliances to complex industrial machinery. At the heart of this industry are the components that make electrical devices functional, durable, and safe. Among these, fasteners play a critical

The electrical equipment industry relies heavily on the efficient functioning of electronic components, and battery holders play a critical role in ensuring the reliability and longevity of electrical devices.

The electrical equipment industry is an essential sector, powering homes, industries, and communication networks. The efficiency, reliability, and safety of electrical systems depend heavily on the quality of components used in these systems.

In today’s rapidly evolving technological landscape, the Electrical Equipment Industry is pivotal in shaping industries ranging from manufacturing and automation to telecommunications and healthcare. One of the fundamental components in this sector is the chassis—the protective enclosure that safegu

In the world of precision engineering, guide pins play a crucial role in ensuring accuracy, stability, and proper alignment in various industrial applications. Whether used in molds, machines, or fixtures, these essential components help maintain positional accuracy and mechanical efficiency.The gui

IntroductionIn the rapidly evolving COMMUNICATION EQUIPMENT INDUSTRY, the demand for efficient, reliable, and high-performance components is ever-increasing. As communication devices become more compact and sophisticated, manufacturers seek materials that can meet stringent requirements for durabili

OverviewClick here to edit your content.Product DescriptionClick here to edit your content.Packaging & ShippingClick here to edit your content.Our Services1.Click here to edit your content.2.Click here to edit your content.3.Click here to edit your content.Company InformationClick here to edit your

IntroductionIn the rapidly evolving COMMUNICATION EQUIPMENT INDUSTRY, the demand for robust, efficient, and reliable components is at an all-time high. Factories, channel providers, and distributors are constantly seeking materials and solutions that not only meet but exceed industry standards. Amon

You use air dust filters to keep electrical equipment safe in cnc milling services. Dust and tiny particles can hurt your equipment and make it not last as long. Filters take dust out of the air, so your cnc workspace stays clean and works well. Filtration solutions like pleated and HEPA filters are