Shenzhen Wandanan Precision Technology Co., Ltd Info@szwandaancnc.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-07-09 Origin: Site

Traditional energy equipment manufacturing often relies on large batch runs, loose tolerances, and lengthy lead times. Components such as frames, enclosures, and structural parts were typically machined or fabricated with tolerances of a few tenths of a millimeter, necessitating extensive manual fitting and welding. These approaches lead to suboptimal performance, higher scrap rates, and extended downtime when components fail or require replacement.

Now, precision manufacturing technologies—CNC machining, five-axis simultaneous milling, laser cutting, laser welding, and advanced grinding—are disrupting this model. By delivering exacting tolerances, superior surface finishes, and drastically reduced setup times, these methods enable the production of energy equipment components that are more reliable, longer-lasting, and quicker to assemble.

Modern CNC machines achieve tolerances as tight as ±0.02 mm (20 microns) on complex parts. Energy equipment components benefiting from this accuracy include:

Frames and Enclosures: Precision milling ensures panel flatness within 0.02 mm across large surfaces. This precision enables gaskets to compress evenly, preserving IP ratings and preventing field failures.

Conductive Strips and Busbars: Copper or aluminum strips machined to ±0.02 mm maintain uniform cross-section and low contact resistance, minimizing hotspots under high current loads (300–600 A).

Heat Sink Fins and Cooling Channels: CNC-machined heat sinks from aluminum or copper feature precise fin spacing and flat mounting surfaces, ensuring consistent thermal interface performance. A 20-micron deviation can degrade thermal conductivity by 5–7%, shortening component life.

Key CNC advancements reduce setup times and boost repeatability:

Quick-Change Pallets: Allow loading raw material on one pallet while the machine runs another, cutting idle time to minutes.

Integrated Probing: Automated touch probes measure part position after clamping, adjusting offsets on the fly. Fixture alignment time drops from 30 minutes to under 5.

Tool Libraries and Automated Changers: Machines swap among 30–60 tools in seconds, enabling complex parts—such as multi-level frames or enclosures—to be completed in one run.

These features shrink lead times from weeks to days. When machined to consistent ±0.02 mm tolerances, parts become fully interchangeable, reducing assembly times by eliminating manual fitting.

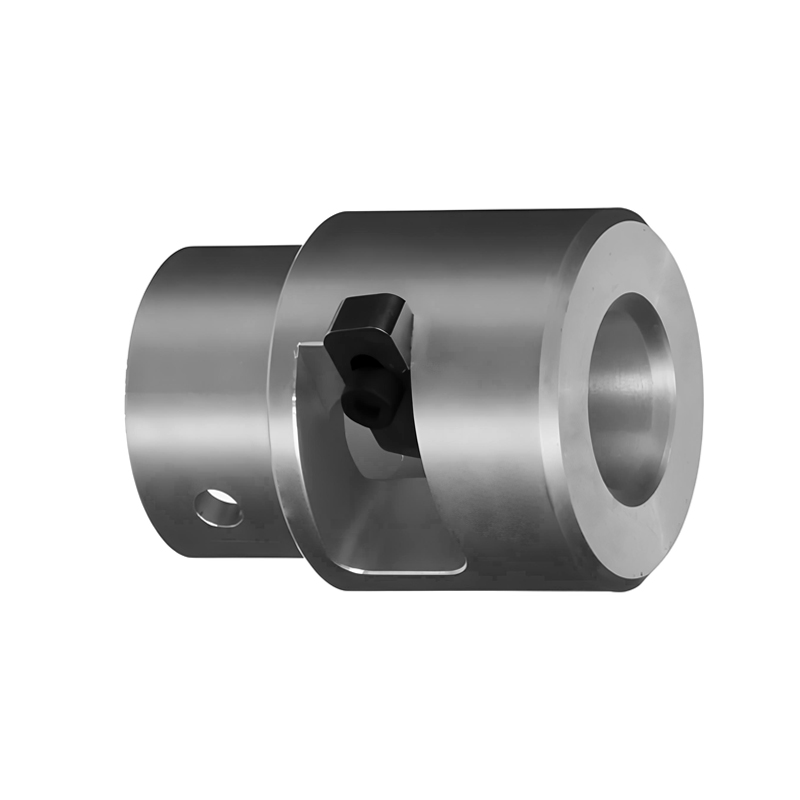

Five-axis machining centers, with axes X, Y, Z plus rotations A (around X) and B (around Y), can reach virtually any surface in a single setup. This capability eliminates multiple fixturing steps, reducing cumulative errors and saving hours of downtime. Benefits include:

Reduced Setup Time: Instead of three or four separate setups, a single five-axis program finishes all contoured surfaces. A proper turbine bearing housing, for instance, might finish in one run rather than multiple re-fixturing steps.

Improved Accuracy: Keeping the part in one datum orientation maintains ±0.02 mm tolerances across all surfaces.

Flexibility: Unusual angles—such as 45° oil port intersections or twisted mounting faces—are machined without manual tilting.

Turbine Blade Root Machining: Blade roots with twisted geometries and internal cooling channels are machined to precise dovetail profiles and cooling bore alignments in one setup, reducing scrap in alloys like 17-4 PH stainless steel.

Pump Housing Volute Finishing: Pump volutes receive smooth internal passages in a single five-axis run, achieving 1.6 μm surface finishes that reduce turbulence and improve efficiency.

Turbine Support Brackets: Support brackets with angled oil passages and bolting flanges finish in one clamp, ensuring perfect alignment for high-speed turbine shafts (3,000–5,000 RPM).

By adopting five-axis capabilities, manufacturers eliminate the time-consuming, error-prone practices of multiple fixturing, rapidly producing complex geometries with consistent quality.

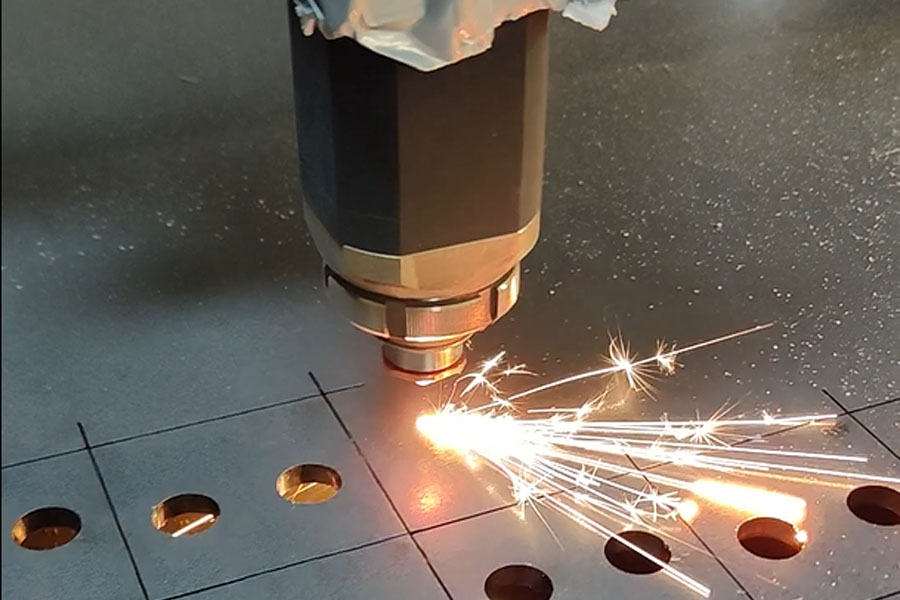

Fiber laser systems now dominate plate processing for enclosures, supports, and panels, offering:

±0.1 mm Cutting Accuracy: Even on 1–20 mm plates, lasers deliver narrow kerf widths (<0.2 mm) and clean edges, reducing the need for secondary milling or grinding.

Minimal Heat-Affected Zone (HAZ): A narrow HAZ (<0.5 mm) minimizes distortion, ensuring 2–5 mm enclosure panels remain flat for IP-rated assembly.

Rapid Nesting and Material Utilization: CAD/CAM nesting packs parts closely, cutting dozens of small brackets or ventilation patterns in minutes, reducing scrap.

A 5 mm stainless steel inverter housing panel with ventilation slots can be laser-cut in under 5 minutes versus 20–25 minutes by traditional punching and shearing. Subsequent deburring, bending, and welding benefit from uniform cut edges.

Laser welding excels when joining high-strength alloys—such as 17-4 PH stainless steel, Inconel, or titanium—where conventional TIG/MIG welding often introduces distortion and necessitates filler material. Laser welding offers:

Precise Heat Input: A focused beam concentrates energy in a narrow zone (<1 mm), producing minimal distortion—a boon for busbar assemblies that feed large current loads.

High Welding Speed: Welding at 2–10 m/min, a 500 mm stainless steel busbar joint that took 20 minutes by TIG finishes in under 2 minutes by laser.

Crack-Free Consistency: Automated tracking adjusts focus dynamically, ensuring uniform penetration. Pump housing assemblies welded by laser remain leak-free under 1.5× rated pressure.

By replacing manual TIG with automated laser welding, manufacturers gain joint consistency, reduced rework, and lower labor costs.

Certain energy components demand exceptionally smooth surfaces for sealing, low friction, or reliable electrical contact. Precision grinding and honing achieve:

Sealing Surfaces: Valve bodies and caps in steam turbine control systems often require Ra ≤ 0.4 μm to prevent high-pressure steam leaks. Grinding wheels with micro-grain abrasives remove microns, delivering mirror-like finishes that withstand 10,000+ operating hours.

Conductive Interfaces: Busbar joint faces need flatness and finish for consistent resistance below 0.1 mΩ. Lapping with diamond slurry achieves these metrics, preventing hotspots under 300–600 A currents and extending joint life.

Heat Exchanger Fins: In oil-cooled power electronics, fin surfaces mated to channel plates require Ra ≤ 0.6 μm. Honed channels produce laminar flow, boosting heat transfer by 10–15% over rough-turned surfaces.

When equipment operates around the clock, longevity is paramount. Precision grinding and honing deliver:

Extended Service Life: Ultra-fine finishes lower wear rates.

Reduced Maintenance: Leak checks and torque inspections are less frequent, saving downtime in remote installations.

Tighter Quality Control: In-line surface measurement prevents out-of-spec parts from progressing downstream, reducing late-stage scrap.

Precision manufacturing—CNC machining, five-axis milling, laser cutting/welding, and advanced grinding—is reshaping energy equipment production. In contrast to traditional approaches with loose tolerances and long lead times, these methods deliver:

Tight Tolerances (±0.02 mm): Critical for enclosures, busbars, and heat sinks, ensuring reliable assemblies and reducing rework.

One-Setup Complex Geometry: Five-axis machining eliminates multiple fixturing steps, enabling rapid, accurate production of intricate parts like turbine hubs and pump volutes.

Efficient Plate Processing and Defect-Free Joints: Laser cutting offers ±0.1 mm accuracy and minimal distortion; laser welding produces consistent, crack-free seams on high-strength alloys.

Ultra-Fine Surface Finishes (Ra ≤ 0.4 μm): Precision grinding and honing guarantee leak-tight seals and low-resistance electrical contacts, extending equipment life and lowering maintenance.

Collectively, these technologies shorten development cycles, improve interchangeability, reduce scrap rates, and enable faster product delivery at lower total cost.

Recommendations for Shenzhen Wandaan Precision Technology Co., Ltd.:

Flexible Process Selection:

Use five-axis machining for large structural parts (frames, housings) to minimize setups.

Apply high-power fiber lasers for sheet and plate cutting of enclosure panels and substructures.

Employ automated laser welding for high-strength alloy joints, replacing manual TIG/MIG.

Hybrid Manufacturing Cells:

Integrate CNC mills, five-axis centers, and laser workstations in unified cells to enable smooth transitions from cutting to finishing, eliminating manual handoffs and reducing handling time.

In-Process Inspection:

Equip CNC centers and grinders with touch probes and profilometers to measure dimensions and roughness on the fly, catching deviations early and reducing rework.

Offer “Wind Turbine Precision Package,” “PV Inverter Rapid Response Package,” or “ESS Cabinet High-Precision Package,” detailing recommended processes, lead times, and tolerances to showcase Wandaan’s expertise.

By leveraging precision manufacturing, Wandaan can help clients in wind power, solar, energy storage, and beyond meet stringent performance demands, driving innovation and competitiveness in the energy equipment industry.