- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-06-09 Origin: Site

Power enclosures—whether inverters, distribution cabinets, or UPS racks—are essential in modern energy systems. At their core, conductive strips (busbars) provide reliable electrical connections, distribute current, and often assist with thermal management. However, the demands on these strips differ dramatically across various applications. In wind turbine inverter cabinets, they must handle high inrush currents, resist corrosion, and withstand vibration. In photovoltaic (PV) inverters, they face continuous high DC loads and temperature extremes. Energy storage system (ESS) cabinets require rapid discharge capability and dynamic load balancing, while data center and industrial automation power cabinets demand precision low-voltage, high-current distribution with redundancy.

Wind turbine inverters convert variable-frequency AC from the generator into grid-compatible AC. During startup and shutdown, inverters experience current surges two to three times greater than normal operating current. Conductive strips in these cabinets must therefore carry continuous currents (often 400–800 A) while surviving short-duration inrush events without excessive heating. Undersized strips risk high I²R losses, leading to hot spots that degrade insulation, solder joints, and joint hardware over time.

To address these demands, engineers typically select high-conductivity copper or tin-plated copper strips. Copper's resistivity is approximately 1.68 × 10⁻⁸ Ω·m at 20 °C, increasing to about 2.53 × 10⁻⁸ Ω·m at 100 °C. By choosing a cross-sectional area large enough to limit temperature rise—often 1.2 to 1.5 times the calculated minimum—designers ensure that even during inrush events, strip temperatures remain below 75 °C. Tin plating (5–10 µm) provides additional protection against oxidation and maintains good solderability and contact performance.

Offshore wind farms exacerbate design challenges: salt spray induces corrosion, and continuous mechanical vibration can loosen bolted connections or fatigue busbar material. Tin-plated copper strips resist salt-induced corrosion, while nickel-plated stainless steel offers even greater chemical inertness at the cost of higher resistivity. To safeguard strip integrity under vibration, mounting hardware incorporates spring washers and lock nuts that maintain consistent clamping pressure over time.

Case Study: A 5 MW offshore wind inverter cabinet originally used bare copper strips (40 mm × 5 mm). Corrosion and loosening bolts led to temperature spikes and maintenance visits every three months. Upgrading to tin-plated copper strips (40 mm × 8 mm) with spring-lock washers eliminated corrosion-related issues. Infrared inspections confirmed no bolted-joint loosening over six months, and maximum strip temperature stabilized at 65 °C under full load. Annual maintenance intervals replaced the previous quarterly schedule, significantly reducing operating costs.

In large-scale PV installations, inverters handle DC currents from multiple solar strings—typically 300 A or more per string. Conductive strips must carry these currents continuously under full sun, often exceeding 50 °C ambient. Aluminum busbars (6061-T6) offer a lightweight alternative to copper, but require cross-sectional areas about 1.6 times larger to match copper's conductivity. For example, a 300 A copper strip might be 40 mm × 6 mm, whereas aluminum might need 40 mm × 10 mm. Copper's thermal conductivity (≈385 W/m·K) also aids in dissipating heat, but its higher density increases weight—an important consideration for rooftop installations.

Aluminum's thermal expansion coefficient (≈23 × 10⁻⁶/K) exceeds copper's (≈16.5 × 10⁻⁶/K). In desert locations, ambient can reach 45 °C, causing busbars to expand. Without accommodation for this movement, bolted joints risk loosening or stress fractures. Designers address this by incorporating flexible braided jumpers near bolted connections, allowing small relative movements without compromising contact integrity. In colder climates, copper's superior low-temperature ductility (remaining pliable below –40 °C) often makes it the preferred choice.

Case Study: A 250 kW rooftop PV inverter in a subtropical region initially used aluminum strips (50 mm × 4 mm). Temperature monitoring revealed DC bus temperatures of 85 °C under 45 °C ambient, exceeding the inverter's 75 °C rating. Replacing aluminum with copper strips (40 mm × 6 mm), coupled with extruded aluminum backplane heat sinks and flexible jumpers, reduced peak bus temperatures to 65 °C. The copper strips also allowed a more compact internal layout, shortening cable runs by 15% and reducing system losses by 1.5%.

Grid-scale lithium-ion ESS cabinets must handle rapid discharge during peak demand or frequency regulation—often at 1C (full discharge in one hour) or higher. A 10 MW system may consist of hundreds of battery racks, each requiring DC busbars capable of 500–1000 A continuous and surging beyond that during protection tests. Conductive strips in these cabinets must minimize voltage drop (tens of millivolts can trigger battery under-voltage protection) and endure frequent discharge cycles without excessive heating.

In microgrid or hybrid power configurations, batteries, solar inverters, and generators connect in parallel, sharing dynamic loads. Conductive strips must exhibit uniform impedance to ensure balanced current distribution. Typically, parallel copper busbar pairs are used for redundancy: two strips, each rated for half the total current, operate in tandem. If one strip degrades or fails, its parallel partner temporarily carries the full load until maintenance occurs. Achieving voltage-drop differences below 5 mV under combined loads ensures even current distribution and prevents overloading a single path.

Case Study: A 10 MW/40 MWh ESS cabinet originally used tin-plated copper strips (100 mm × 8 mm) rated at 1000 A each. Fast discharge tests at 1C caused bus temperatures to exceed 90 °C, above the 75 °C rating. Engineers increased strip cross-sections (120 mm × 10 mm), upgraded cooling fans, and added aluminum backplane pads. As a result, bus temperatures stayed under 70 °C during 1C discharge, and voltage imbalances between parallel strips dropped to less than 5 mV at 2000 A combined current. Six-month operation saw no busbar-related faults, validating the improvements.

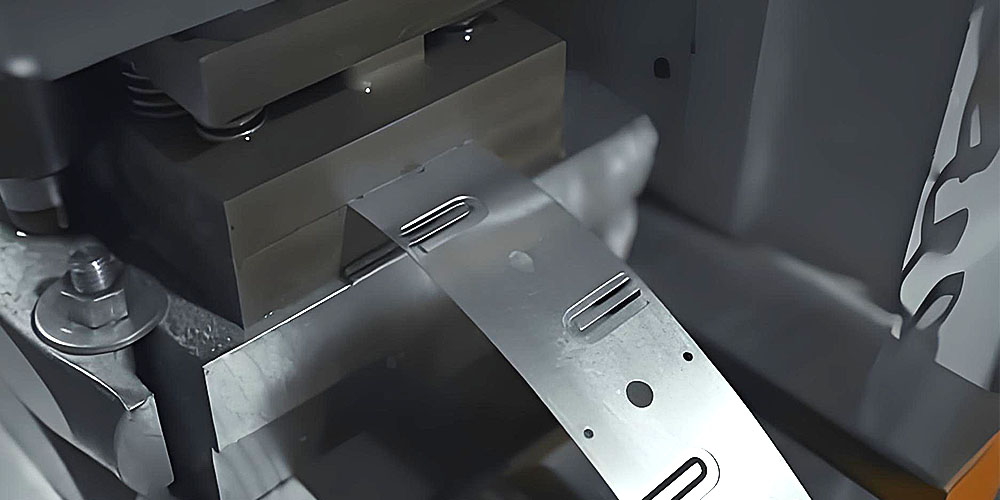

Automation panels and data center UPS racks often require low-voltage (48 V to 220 V) but high-current (100 A to 1000 A) busbars. Traditionally, thick copper cables handled these currents, but cables are bulky, sagging under their own weight, and complicate airflow. Conductive strips—such as 80 mm × 5 mm copper—offer comparable current capacity with a slimmer profile, improving cabinet organization and reducing impedance.

High-availability data centers employ 2N redundancy: two identical power paths each rated to carry the entire load. In a 1 MW UPS cabinet, for instance, two copper busbars (80 mm × 6 mm each at 1000 A) operate in parallel. Even minor impedance mismatches (tens of micro-ohms) can skew current sharing, leading one strip to overheat. To achieve balanced sharing, busbar lengths must be identical, cross-sections machined to precise tolerances (±0.5 mm), and contact surfaces finished to Ra ≤ 0.8 µm. Bolts are torqued uniformly—often using calibrated wrenches—to maintain equal clamping pressure.

Case Study: A tropical data center installed a 1 MW UPS with 2N busbars. Initial tests revealed a 10 mV voltage drop difference at 800 A, causing one strip to carry 55% of the current and reach 65 °C while the other remained at 58 °C. Replacing the secondary strip with a slightly thicker 80 mm × 6.2 mm busbar equalized impedance, reducing voltage drop difference to 2 mV at 1000 A. Uniform bolt torque (12 Nm) and an insulating polyester spacer minimized stray currents. Under full load, both busbars carried 500 A ± 1%, with temperatures stabilizing at 60 °C. Simulated failure tests confirmed seamless switchover—no voltage sag or disruption—ensuring continuous operation.

Investing in well-designed conductive strips is essential for safe, efficient power distribution across diverse energy applications—whether managing high inrush currents in wind turbines, continuous DC loads in PV inverters, rapid discharge events in ESS cabinets, or redundant low-voltage feeds in data centers. Key strategies include choosing the right material (e.g., pure or tin-plated copper for high current, nickel-plated stainless steel for corrosion resistance, or aluminum for lightweight installations), sizing cross-sections with a 1.2–1.5× safety margin, integrating heat-dissipating backplates or fans, and using spring washers or flexible jumpers to maintain reliable contacts under vibration and thermal cycling. Proper surface finishes (Ra ≤ 0.8 µm), uniform bolt torques, and adequate creepage distances further prevent faults, while appropriate plating (tin, nickel, epoxy) protects against salt spray, acid vapors, or dust.

For turnkey conductive strip solutions—including material selection, engineering design, surface treatments, and onsite technical support—Shenzhen Wandaan Precision Technology Co., Ltd. offers unmatched expertise. Their team guides you from initial load calculations to prototype samples and final installation, ensuring your power enclosure performs reliably and cost-effectively. To explore tailored options, request datasheets, or schedule a consultation, please visit Shenzhen Wandaan Precision Technology Co., Ltd. or contact their technical specialists directly.