- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: summy Publish Time: 2025-03-27 Origin: Site

HOW'S THE CNC MACHINING PROCESSING

The CNC machining process involves a sequence of steps where a

computer-controlled machine uses a cutting tool to shape or remove

material from a workpiece to create precise parts. The process can vary

depending on the type of CNC machine being used (CNC lathe,CNC milling machine),

but the core principles are similar.

| 1. Design and Programmin |

CAD (Computer-Aided Design): The process starts with creating a digital 3D model of the part to be machined using CAD software. The design contains all the geometrical specifications for the part. CAM (Computer-Aided Manufacturing): After the design is complete,CAM software is used to convert the CAD model into machine-readable instructions (usually in G-code). These instructions tell the CNC machine how to move,which tools to use, and how to cut the material. G-code: This is a programming language that dictates the machine's movements,speeds,tool changes,and more. It is generated by the CAM software and uploaded to the CNC machine. |

| 2.Material Setup |

Material Selection: Depending on the part design,you select a suitable material (e.g.,aluminum,stainless steel,plastic,etc.). The material comes in various forms like blocks,bars,or sheets. Fixturing: The workpiece is securely clamped or fixtured onto the CNC machine table or spindle. Proper fixturing ensures that the part doesn't move during machining,ensuring accuracy. |

| 3. Machining Process |

| Tool Selection: Based on the part design,specific cutting tools (end mills,drills,lathes,etc.) are chosen. The type of tool depends on the material and the complexity of the part. Cutting and Shaping: The CNC machine follows the G-code instructions and begins the cutting process. The tool moves along multiple axes (usually 3,4,or 5-axis),removing material in the desired shape. The process may involve: Milling: Cutting and shaping the material using rotating tools (usually for flat or 3D surface features). Turning: Rotating the workpiece while a stationary cutting tool removes material (used for cylindrical parts). Drilling: Making holes or other types of openings in the workpiece. Grinding: Achieving fine surface finishes and precision tolerances. |

| 4. Tool Changes & Adjustments |

| Tool Changes: CNC machines typically have an automatic tool changer (ATC). When the part design requires different tools,the CNC machine will automatically swap them. Adjustments: The program may include pauses for tool changes,tool length adjustments,or monitoring and measuring the part to ensure tolerances are maintained. |

| 5. Finishing and Inspectio |

After the machining is complete,the part is removed from the fixture. The part is often inspected for accuracy,surface finish,and tolerance using tools like micrometers,calipers,or even advanced CMM (coordinate measuring machines). Any necessary finishing processes (e.g.,polishing,deburring,coating) may be applied to improve the part's surface quality or functionality. |

| 6. Quality Control |

Post-machining Inspection: Parts are inspected to ensure they meet the required specifications for dimensions,tolerances,and surface finish. Testing: In some industries (e.g.,aerospace,medical),parts may undergo additional testing like stress tests or functional testing. |

CNC Milling

CNC Lathe(Turning)

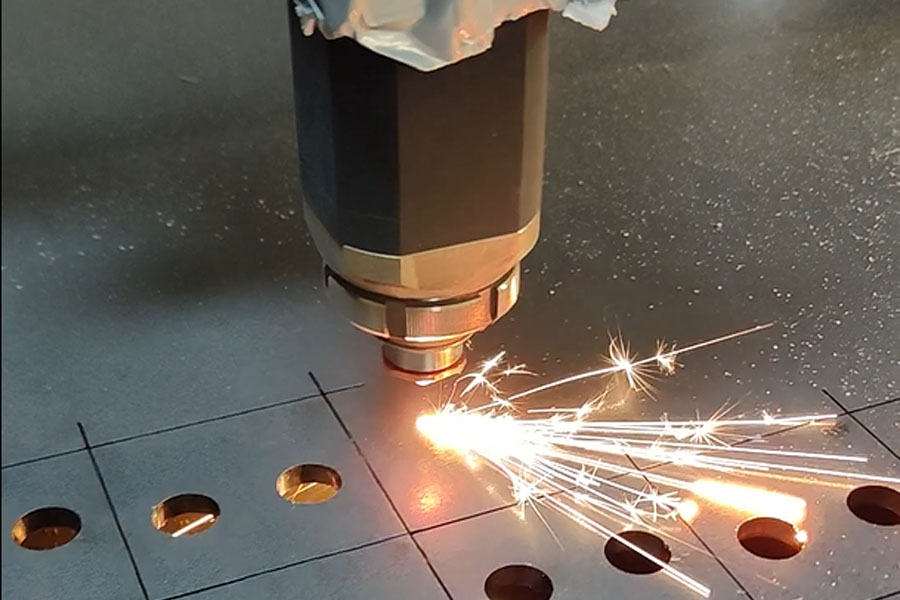

Laser Cutting

CNC Drillings

| Key Benefits of CNC Machining |

Precision: CNC machines can produce parts with extremely tight tolerances and repeatability,often down to microns. Automation: CNC machines operate automatically based on the program,reducing human error. Versatility: CNC can machine complex shapes and geometries that would be very difficult or time-consuming to create manually. Efficiency: High-speed machining capabilities enable rapid production of parts,making it ideal for both prototyping and mass production. Consistency: Once the CNC program is set up,the machine can replicate the same part hundreds or thousands of times with minimal deviation. |

| Conclusion |

CNC machining is a precise,efficient,and flexible manufacturing process. It involves using computer programs to control machines that remove material from a workpiece,resulting in highly accurate and repeatable parts. Whether it's a one-off prototype or a mass production run,CNC machining is widely used across industries like aerospace,automotive,medical devices,and more. |