SHENZHEN WANDA-AN PRECISION TECHNOLOGY CO.,LTD Info@szwandaancnc.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

CNC TURNING MACHINING SERVICE

What’s the Turning Milling ?

Turning and Milling are two fundamental machining processes used in manufacturing to shape and refine materials,typically metals.Each process uses different tools and techniques to achieve specific geometries and features on work-pieces.

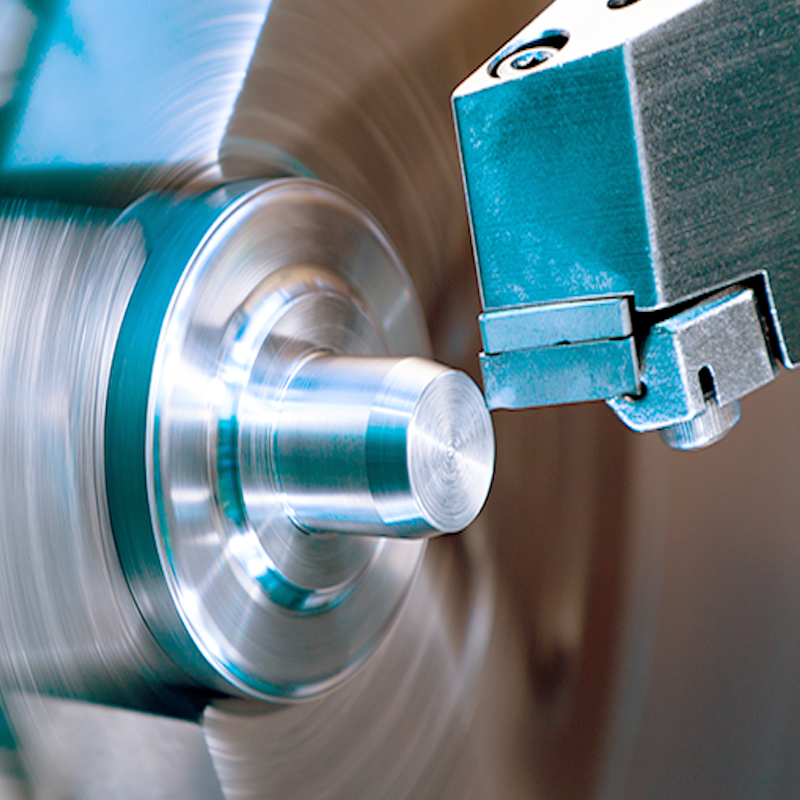

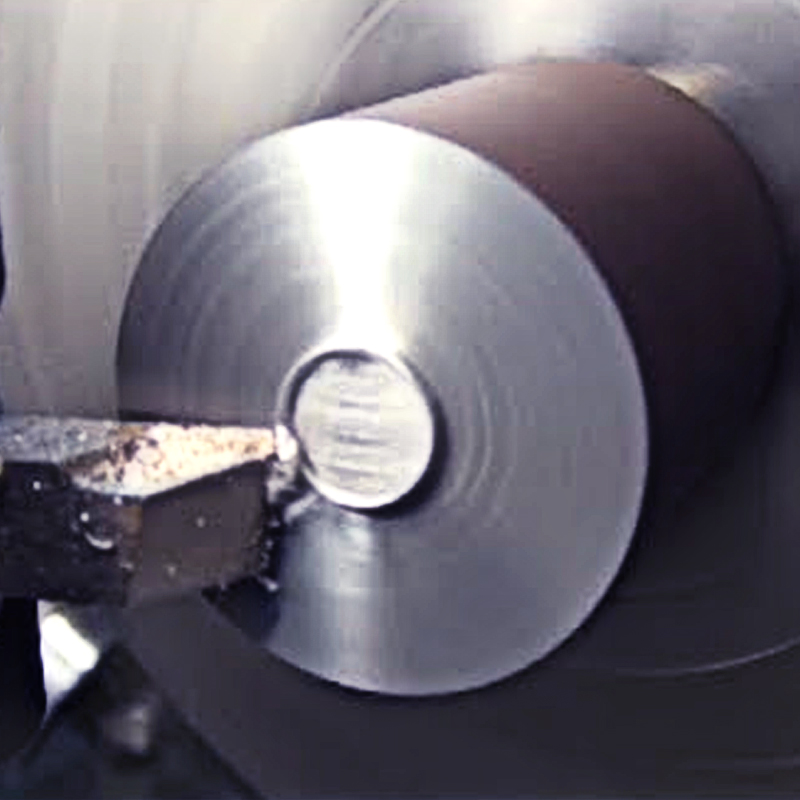

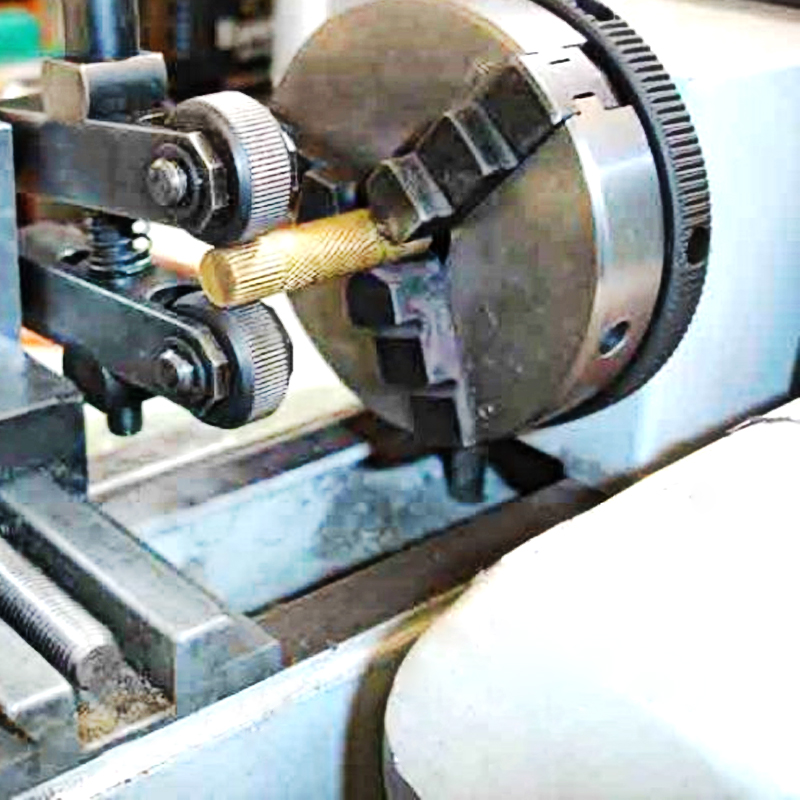

Turning is a machining process that involves rotating a workpiece on a lathe while a cutting tool removes material to create cylindrical shapes or features. Here are the key aspects of turning:

Process: The workpiece is mounted on a spindle and rotated at high speed. A stationary cutting tool moves in a linear path along the workpiece to remove material.

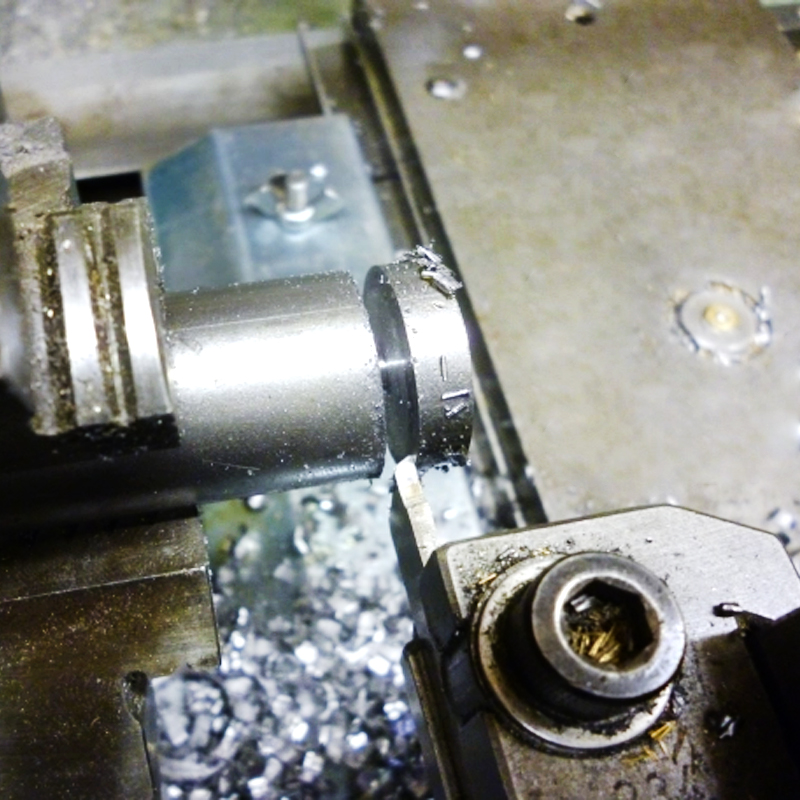

Applications: Turning is used to produce cylindrical parts,such as shafts,pins,and bushings. It can create various features,including grooves,threads,and tapered surfaces.

Tools: The primary tool used in turning is a single-point cutting tool,which can be made from high-speed steel (HSS),carbide,or ceramic materials

Milling is a machining process that involves removing material from a workpiece using rotary cutters.The workpiece is typically held stationary while the cutter moves to create flat surfaces, slots,or intricate shapes.Here are the key aspects of milling:

Process: In milling, a rotating cutter moves across the work-piece,removing material as it advances. The cutter can move in multiple axes, allowing for more complex shapes.

Applications: Milling is used to produce a wide range of components,such as gears, brackets, and custom parts with complex geometries. It can create flat surfaces,key ways,and contoured profiles.

Tools: Milling tools include end mills,face mills,and drill bits, which can be made from HSS, carbide,or other cutting materials.

THE TYPES OF THE TURNING MACHINING

Turning machining is a versatile process used to create cylindrical parts and components by removing material from a rotating work-piece.Various types of turning operations can be performed depending on the desired shape,size,and features of the finished parts.

Straight Turning

Taper Turning

Facing MACHINING

Thread Turning

Thread Turning

Grooving Machining

Parting Off

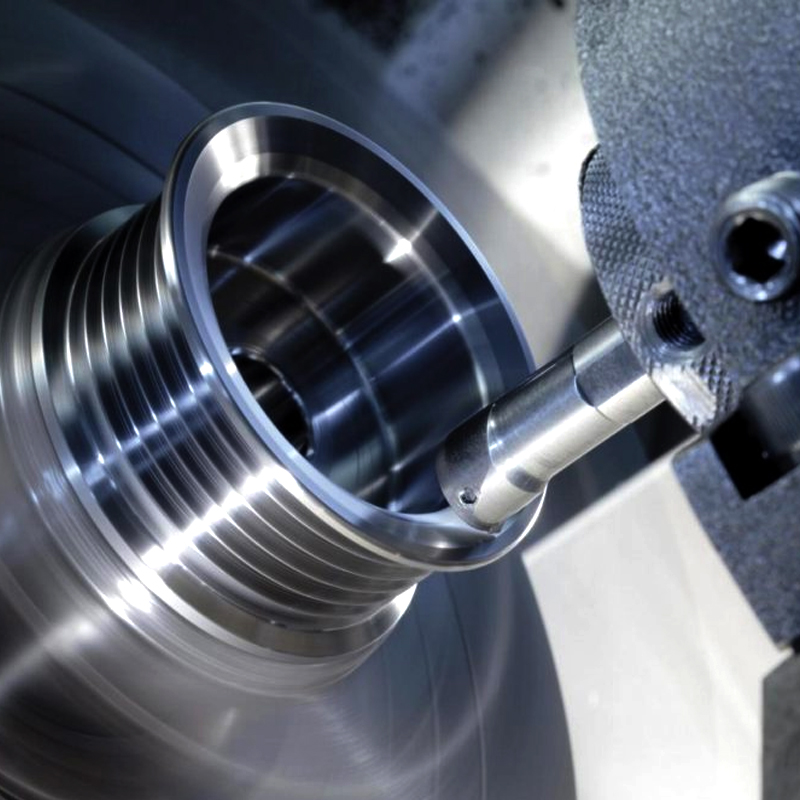

Boring Machining

Knurling Machining

Cam Turning Machining

CNC Turning Machining

The Types of the Milling Machining

Milling machining is a versatile manufacturing process used to remove material from a work-piece using rotary cutters. The type of milling operation can vary based on factors such as the orientation of the cutter, the type of milling machine used, and the desired shape of the finished part. Here are the main types of milling machining:

1. Horizontal Milling

Description: In horizontal milling, the cutter is mounted on a horizontal spindle. The work-piece is fed horizontally into the rotating cutter.

Application: Ideal for producing flat surfaces, grooves, and key ways. Commonly used for heavy-duty milling operations.

2. Vertical Milling

Description: Vertical milling features a cutter mounted on a vertical spindle. The work-piece can be moved up and down to create various shapes.

Application: Suitable for creating slots, pockets, and complex shapes. Often used in small to medium production runs.

3. Universal Milling

Description: Universal milling machines can perform both vertical and horizontal milling operations. They often feature adjustable table positions and can accommodate various tooling.

Application: Versatile for different milling tasks, allowing for complex parts and profiles.

4. CNC Milling

Description: CNC (Computer Numerical Control) milling uses computerized controls to automate the milling process. It allows for high precision and repeatability.

Application: Ideal for complex geometries, high-volume production, and precision parts in various industries.

5. Face Milling

Description: Face milling uses a flat cutter to remove material from the surface of the work-piece. The cutter's axis is perpendicular to the work-piece surface.

Application: Commonly used to create flat surfaces, steps, and profiles on the work-piece.

6. End Milling

Description: End milling involves using a rotating cutter with cutting edges on the end and the sides. It can be performed on both vertical and horizontal milling machines.

Application: Suitable for producing complex shapes, slots, and contours in the work-piece.

7. Slot Milling

Description: Slot milling uses a specialized cutter to create slots or grooves in the work-piece.

Application: Commonly used for producing key ways, T-slots, and other features requiring precise slot dimensions.

8. Tapping

Description: Tapping involves creating internal threads in a work-piece using a rotating tool called a tap.

Application: Widely used to prepare holes for screws or bolts, allowing for secure fastening.

9. Drilling

Description: While primarily a separate process, drilling can be performed on milling machines using drill bits to create holes in the work-piece.

Application: Used for producing holes of various sizes and depths in parts.

10. Profile Milling

Description: Profile milling involves creating complex shapes by following a predefined contour or profile on the work-piece.

Application: Commonly used for producing intricate designs and shapes in parts, such as molds and dies.

11. Plunge Milling

Description: Plunge milling involves inserting the cutter straight down into the workpiece rather than moving it horizontally. This method is often used for heavy cuts.

Application: Suitable for machining deep slots or cavities where traditional milling might not be effective.

12. Contour Milling

Description: Contour milling is used to create curved or irregular shapes on the work-piece surface by following the outline of a specific contour.

Application: Commonly used for molds, dies, and other applications requiring non-linear features.

The Process of Turning&Milling

The turning-milling process is a hybrid machining method that combines turning and milling operations to produce complex geometries on a workpiece. This process is typically performed on specialized CNC machines that have the capabilities of both turning and milling, often referred to as turning centers or multi-tasking machines. Here’s an overview of the turning-milling process:

Overview of the Turning-Milling Process

Setup and Tooling:

The workpiece is securely clamped in the machine's spindle, which rotates the part during the turning operation.

Various cutting tools are mounted on a tool turret or a tool holder, enabling both turning and milling operations. These tools may include turning inserts, end mills, face mills, and drilling tools.

Turning Operation:

The process typically begins with the turning operation, where the rotating workpiece is machined using a single-point cutting tool.

The tool removes material from the outer diameter, creating cylindrical shapes, reducing the diameter, or forming features like grooves and threads.

Milling Operation:

After the turning operation, the machine can switch to milling mode. The cutting tool (often a rotating end mill) engages with the workpiece to create flat surfaces, slots, or complex contours.

The milling can occur at various angles and depths, allowing for detailed features to be added to the workpiece.

Tool Path Programming:

The entire process is controlled by a CNC (Computer Numerical Control) system, which allows for precise programming of the tool paths and machining parameters.

Operators can use CAD/CAM (Computer-Aided Design/Computer-Aided Manufacturing) software to design the part and generate the necessary code for the CNC machine.

Simultaneous Operations:

In advanced turning-milling machines, both turning and milling can occur simultaneously, significantly reducing cycle times and increasing productivity.

This capability allows for more complex geometries to be created in a single setup, minimizing the need for additional handling and setups.

Advantages of the Turning-Milling Process

Increased Efficiency: By combining turning and milling operations, manufacturers can significantly reduce production times and improve efficiency.

Complex Geometries: This process allows for the creation of complex shapes and features that would be challenging to achieve with either turning or milling alone.

Improved Precision: CNC control provides high levels of accuracy and repeatability, essential for modern manufacturing standards.

Reduced Setup Time: Performing multiple operations in a single setup minimizes handling and setup time, leading to quicker turnaround times for production.

Applications of the Turning-Milling Process

The turning-milling process is widely used in various industries, including:

Aerospace: For manufacturing complex components such as turbine housings, brackets, and precision fittings.

Automotive: For producing engine parts, transmission components, and other intricate assemblies.

Medical Devices: For creating precision instruments and implants with complex shapes.

Oil and Gas: For producing components that require high durability and precision, such as valve bodies and fittings.