Shenzhen Wandanan Precision Technology Co., Ltd Info@szwandaancnc.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

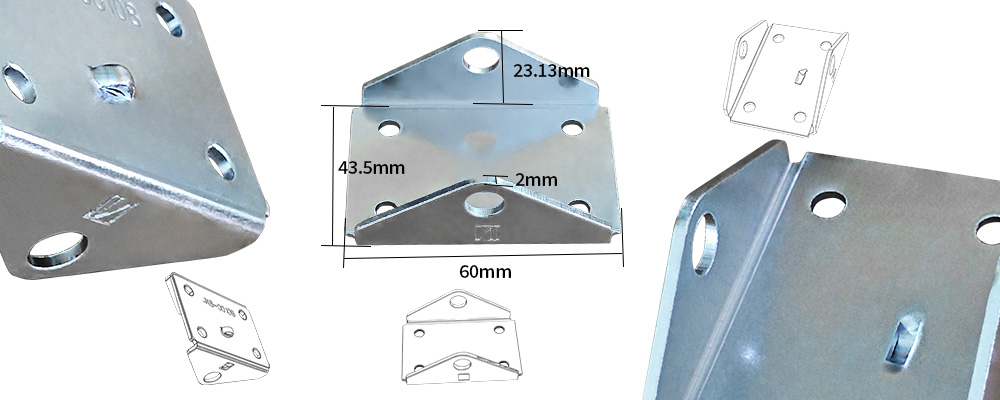

Caster Wheel Bracket

At Wanda-an, we produce various types of sheet metal brackets for casters wheel, from cutting to stamping, bending, and one-stop manufacturing services, providing customers with stable quality caster brackets. These brackets come in diverse designs, including swivel and fixed types, to cater to specific mobility needs. Swivel brackets allow 360-degree rotation for maneuverability, while fixed brackets offer stability in straight-line movement.

1. Applications of Caster Wheel Bracket

Caster wheel brackets are unsung heroes of mobility, enabling seamless movement across diverse sectors. Their adaptability stems from customizable designs, materials, and load capacities, making them indispensable in environments where efficiency and safety are paramount.

In factories, heavy-duty steel brackets with swivel mechanisms facilitate the transport of machinery and assembly lines. Locking features prevent unintended shifts during operation, while reinforced frames withstand repetitive stress. For example, automotive plants use them to move robotic arms, reducing downtime and worker fatigue.

Hospitals prioritize hygiene and patient safety. Stainless steel or plastic brackets with smooth-rolling wheels ensure quiet, vibration-free movement of medical carts and beds. Non-marking wheels protect flooring, and anti-static options are critical in operating rooms where electric discharge risks must be minimized.

Distribution centers rely on high-capacity brackets to maneuver pallets and forklifts. Adjustable height designs accommodate uneven surfaces, while double-wheel configurations enhance stability for bulky loads. In cold storage units, corrosion-resistant brackets endure extreme temperatures without compromising mobility.

Retail stores and offices benefit from lightweight aluminum brackets for furniture like display racks and office chairs. Swivel wheels allow effortless navigation in tight spaces, and noise-reducing features maintain a quiet ambiance.

2. Products details

| Material | Stainless, Aluminum, etc. |

| Type | Universal bracket, swivel bracket, customer's requirement |

| Application | Furniture caster wheel, industrial caster wheel, medical caster wheel, etc. |

| Size | 1inch, 1.5 inch, 2inch, 3inch, 4inch, customized |

| Surface Treatment | Zinc-plated, anodized, customized |

| Option | Brack, fixed, swivel |

Shenzhen Wandaan Precision Technology Co.,ltd was founded in 2001, focusing on CNC machining and sheet metal fabrication services for over 20 years. we specialize in manufacturing stamping services, sheet metal fabrication, and Cnc machining services. With a specialist team of skilled welders, mechanical engineers, fabricators and designers, there's no project or installation job too big or too small for us.

3. FAQ

Q: What document will need the customer to provide?

You could provide 2D/3D drawing or send your sample to our factory, then we can make sample according to your document.

Q: Can we sign NDA?

Of course, we will protect the customer private right once sign the NDA.

Q: Can you provide sample?

Yes, we can provide you sample before mass production.

Q: How can you ensure the quality?

We have the professional QC department to gurantee the quality.

Q5: Delivery time

If in stock: Around 3 days after payment. Mass production: Around 20-30 days after receiving the deposit.(Accurate delivery time depends on the specific items and quantities)

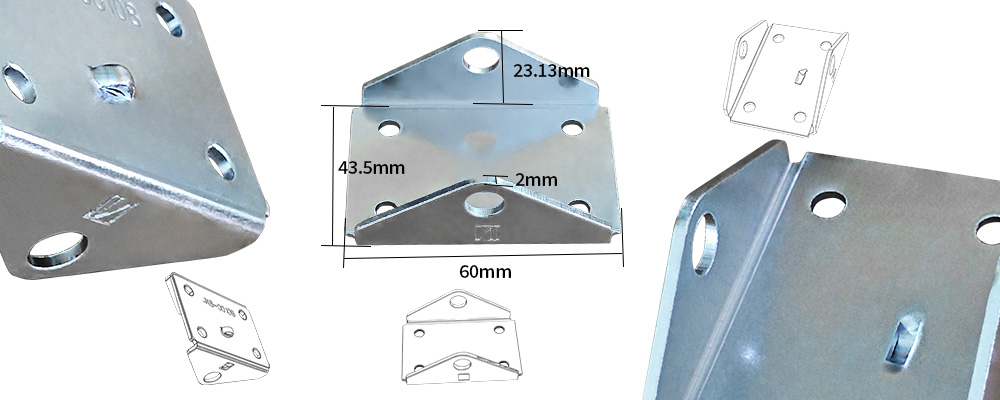

Caster Wheel Bracket

At Wanda-an, we produce various types of sheet metal brackets for casters wheel, from cutting to stamping, bending, and one-stop manufacturing services, providing customers with stable quality caster brackets. These brackets come in diverse designs, including swivel and fixed types, to cater to specific mobility needs. Swivel brackets allow 360-degree rotation for maneuverability, while fixed brackets offer stability in straight-line movement.

1. Applications of Caster Wheel Bracket

Caster wheel brackets are unsung heroes of mobility, enabling seamless movement across diverse sectors. Their adaptability stems from customizable designs, materials, and load capacities, making them indispensable in environments where efficiency and safety are paramount.

In factories, heavy-duty steel brackets with swivel mechanisms facilitate the transport of machinery and assembly lines. Locking features prevent unintended shifts during operation, while reinforced frames withstand repetitive stress. For example, automotive plants use them to move robotic arms, reducing downtime and worker fatigue.

Hospitals prioritize hygiene and patient safety. Stainless steel or plastic brackets with smooth-rolling wheels ensure quiet, vibration-free movement of medical carts and beds. Non-marking wheels protect flooring, and anti-static options are critical in operating rooms where electric discharge risks must be minimized.

Distribution centers rely on high-capacity brackets to maneuver pallets and forklifts. Adjustable height designs accommodate uneven surfaces, while double-wheel configurations enhance stability for bulky loads. In cold storage units, corrosion-resistant brackets endure extreme temperatures without compromising mobility.

Retail stores and offices benefit from lightweight aluminum brackets for furniture like display racks and office chairs. Swivel wheels allow effortless navigation in tight spaces, and noise-reducing features maintain a quiet ambiance.

2. Products details

| Material | Stainless, Aluminum, etc. |

| Type | Universal bracket, swivel bracket, customer's requirement |

| Application | Furniture caster wheel, industrial caster wheel, medical caster wheel, etc. |

| Size | 1inch, 1.5 inch, 2inch, 3inch, 4inch, customized |

| Surface Treatment | Zinc-plated, anodized, customized |

| Option | Brack, fixed, swivel |

Shenzhen Wandaan Precision Technology Co.,ltd was founded in 2001, focusing on CNC machining and sheet metal fabrication services for over 20 years. we specialize in manufacturing stamping services, sheet metal fabrication, and Cnc machining services. With a specialist team of skilled welders, mechanical engineers, fabricators and designers, there's no project or installation job too big or too small for us.

3. FAQ

Q: What document will need the customer to provide?

You could provide 2D/3D drawing or send your sample to our factory, then we can make sample according to your document.

Q: Can we sign NDA?

Of course, we will protect the customer private right once sign the NDA.

Q: Can you provide sample?

Yes, we can provide you sample before mass production.

Q: How can you ensure the quality?

We have the professional QC department to gurantee the quality.

Q5: Delivery time

If in stock: Around 3 days after payment. Mass production: Around 20-30 days after receiving the deposit.(Accurate delivery time depends on the specific items and quantities)