SHENZHEN WANDA-AN PRECISION TECHNOLOGY CO.,LTD Info@szwandaancnc.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

What's The CNC Machining Meaning ?

Computer Numerical Control (CNC) is an automated manufacturing process that controls and operates machinery—such as lathes,mills,drills,and more. It has evolved the manufacturing industry as we know it,streamlining the production process and allowing complex tasks to be done with precision and efficiency.

When a CNC system is activated,the desired cuts are programmed into the software and dictated to corresponding tools and machinery,which carry out the dimensional tasks as specified,much like a robot.

In CNC programming,the code generator within the numerical system will often assume mechanisms are flawless,despite the possibility of errors,which is greater whenever a CNC machine is directed to cut in more than one direction simultaneously.The placement of a tool in a numerical control system is outlined by a series of inputs known as the part program.

With a numerical control machine,programs are inputted via punch cards.By contrast,the programs for CNC machines are fed to computers through small keyboards.CNC programming is retained in a computer’s memory.The code itself is written and edited by programmers. Therefore,CNC systems offer far more expansive computational capacity.Best of all,CNC systems are by no means static since newer prompts can be added to pre-existing programs through revised code.

THE Types Of CNC Machinig

In the CNC Process,there have serval Common used Mahining types:

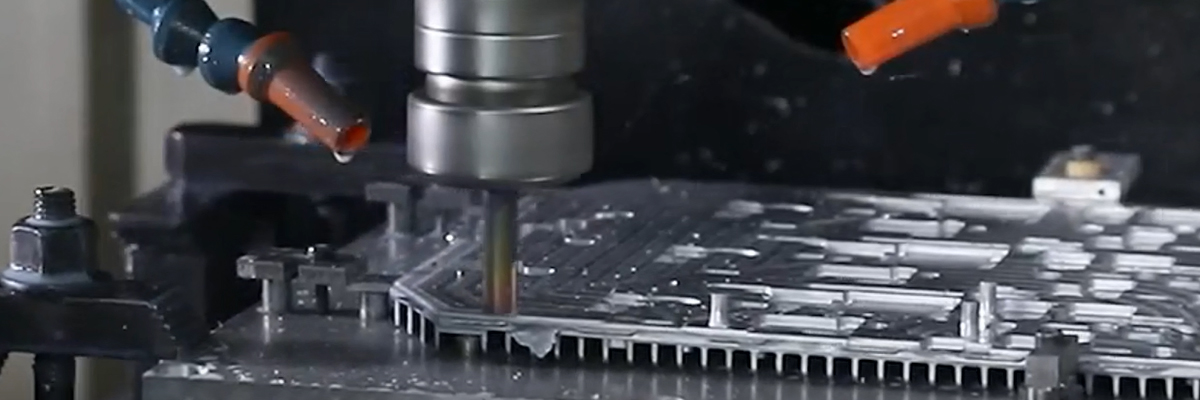

CNC Milling Machinig:

CNC milling involves the use of rotating multi-blade tools to perform cutting operations on Materials Part on a CNC machine.During processing,the milling cutter rotates as the primary motion,while the materials moves as the feed motion.

Before CNC milling,the machining object is analyzed to determine the blank.Once the conditions of the machining object are established,process design follows,including selecting the machining method,process sequence,appropriate tools,and clamping methods.Subsequently,specialized CNC programming software is utilized to create the CNC program based on design requirements.

With the aforementioned preparations complete,the milling machine is adjusted to ensure accurate positioning of the work-piece and tools.The parameters of the data equipment,as well as the tools,clamping devices,and workbench,are then fine-tuned to guarantee accuracy and stability.After confirming the parameters and ensuring the machine is ready for operation,the CNC machine is started,and the pre-set CNC program is run.The system automatically controls the tool to perform precise cutting on the machining object.

Finally,the accuracy and stability of the CNC machine are verified,and testing cutting is performed on the machining object.During this process,adjustments to the equipment,parameters,and clamping devices are made as necessary to ensure the precision of the sample.

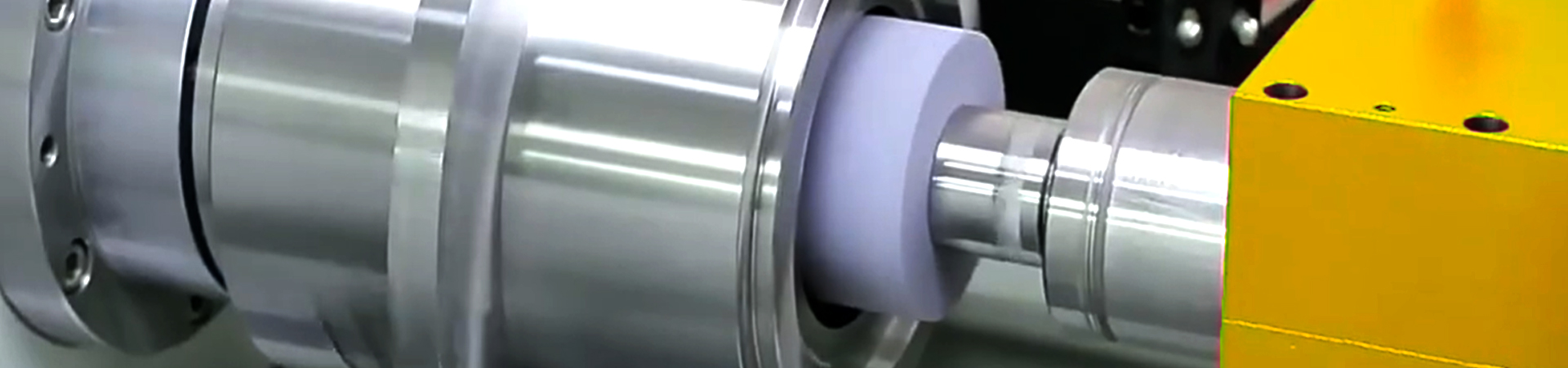

CNC Turning Machining:

Turning is a machining process that involves rotating a workpiece on a lathe while a cutting tool removes material to create cylindrical shapes or features. Here are the key aspects of turning:

Process: The workpiece is mounted on a spindle and rotated at high speed. A stationary cutting tool moves in a linear path along the workpiece to remove material.

Applications: Turning is used to produce cylindrical parts,such as shafts,pins,and bushings. It can create various features,including grooves,threads,and tapered surfaces.

Tools: The primary tool used in turning is a single-point cutting tool,which can be made from high-speed steel (HSS),carbide,or ceramic materials.

Lathe Types:

Engine Lathe: A versatile machine used for general turning operations.

CNC Lathe: A computer-controlled lathe that automates the turning process for precision and complex shapes.

CNC DRILLING MACHINING

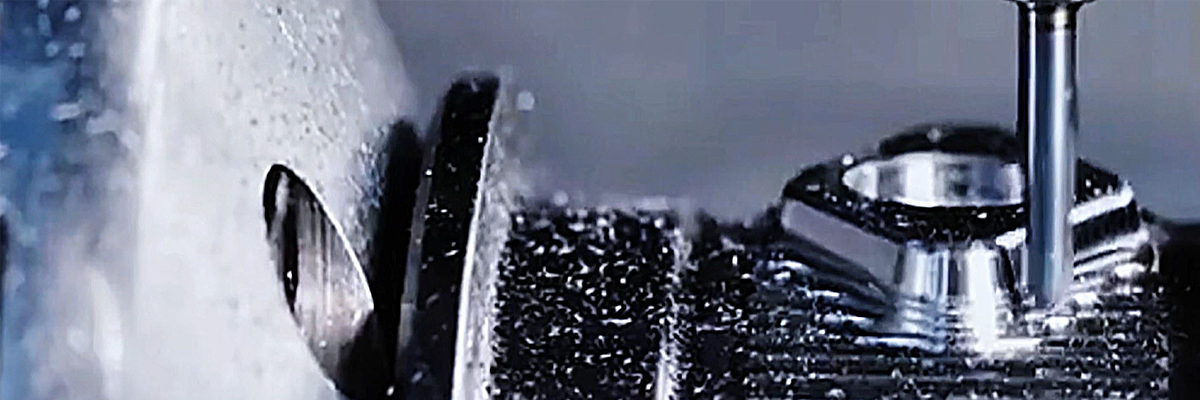

CNC drilling is a process that utilizes precision data-processing lathes to perform drilling operations on various materials.CNC drilling equipment typically includes vertical fully automatic drilling machines,U-shaped drilling machines,and special-shaped dual-axis CNC drilling machines,all of which feature high precision and automation.CNC drilling finds wide application in industries such as automobiles,locomotives,shipbuilding,and aerospace,where it is used for drilling large components with multiple hole patterns,such as ultra-long laminated plates and structural steels.It is also employed in the rubber and plastic mold industry for processing water channels,ejector pin holes,and in the machining of hydraulic machinery parts.

CNC drilling is a type of equipment that performs automatic precision machining through loaded programs.During programming,it is essential to specify parameters such as the position,size,and depth of the holes to be machined, as well as the hardness of the material.Before machining, simulation software or sample drilling is used to adjust the program's accuracy.Subsequently, appropriate cutting tools are selected and parameters are adjusted based on the requirements of the material being processed.

CNC drilling employs circular drilling commands primarily to automate the drilling process,enabling the drilling machine to automatically complete the entire drilling sequence through these commands.The CNC drilling process typically involves rapid tool positioning,quick movement along the Z-axis to the reference plane,deep drilling,and hole bottom processing.

CNC GRINDING MAHCINING

CNC GRINDING,is an indispensable part of modern machining.Below is a brief introduction:

Definition and Principle

Definition:CNC GRINDING is a process that utilizes Computer Numerical Control (CNC) technology to perform grinding operations on Materials.

Principle:By controlling the motion trajectory and parameters of the grinding tool through the CNC system,precise machining of the Materials is achieved.

Characteristics and Advantages

High Precision: The high-precision control of the CNC system ensures the accuracy of grinding operations.

High Efficiency: The automated machining process improves production efficiency.

Flexibility: It can adapt to the processing needs of workpieces of different shapes and sizes.

Application Fields

CNC GRINDING is widely used in various fields such as automobiles, aerospace, and mold manufacturing, for the processing of high-precision parts and complex surfaces.etc