Shenzhen Wandanan Precision Technology Co., Ltd Info@szwandaancnc.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

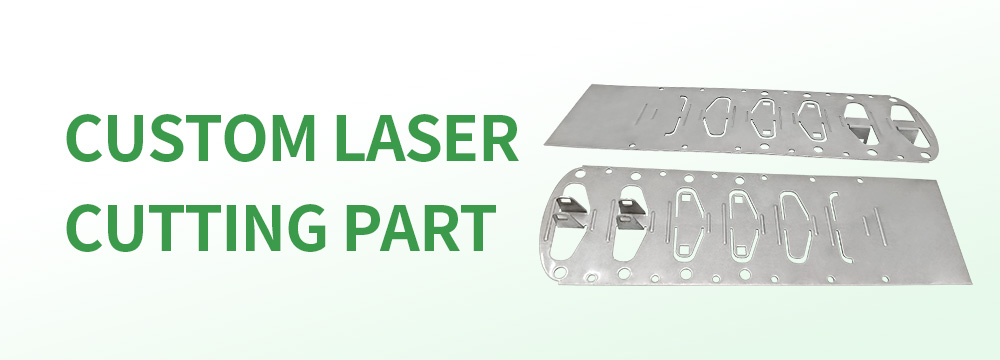

Laser Cutting Stamping Part

In the rapidly evolving fields of electrical engineering and new energy technologies, laser cutting parts have become indispensable components for manufacturing high-precision sheet metal components. This advanced machining technique offers unparalleled advantages in terms of precision, flexibility, and efficiency, making it ideal for applications in electrical enclosures, battery systems, and renewable energy infrastructure.

| Material | Stainless steel, Steel, Copper, Brass, Aluminum, etc. |

| Surface Treatment | Anodizing, Galvanized, Tin-plated, Nickle, Powder Coating, etc. |

| Thichness | 0.1mm-12mm, customized |

| Certification | ISO9001:2015, IATF16949:2016, RoHS |

| Drawing Format | DWG, DXF, STEP, STP, PDF, JPG |

| Application | New Energy, Industry, Electronic, etc. |

Application:

The new energy sector particularly benefits from laser cutting technology:

2. Solar Panel Frames: The technology allows for lightweight yet durable frame designs with minimal material usage, improving overall system efficiency.

Key Applications in Electrical Engineering

1.Enclosures and Cabinets: Laser-cut parts enable the production of complex electrical enclosures with precise cutouts for ventilation, connectors, and mounting points. The technology allows for intricate designs without compromising structural integrity.

2. Busbars and Conductors: The precision of laser cutting ensures clean edges and consistent dimensions for electrical conductors, minimizing resistance and improving current flow efficiency.

The integration of laser cutting technology into electrical and new energy manufacturing processes represents a significant leap forward in component quality and production efficiency. By providing precise, clean-cut parts with minimal material waste, laser cutting technology helps drive innovation across these critical industries. At Wanda-An Precision, we provide laser cutting, stamping, and bending services for your new project.

FAQ:

1. Are you a trading company or a manufacturer?

We are a manufacturer and have been in this field for more than 20 years.

2. How to get a quote?

Please send your 3D drawing(STP, DWG, IGS) to us, and tell us the material, surface treatment, and quantity, then we will quote within 24 hours.

3. What kind of production services do you provide?

Sheet metal fabrication, CNC processing, stamping, laser cutting, bending, welding, assembly, and surface treatment.

4. What kind of surface finish can you provide?

Pulverization, polishing, electroplating, anodizing, hot dip galvanizing, powder coating etc.

5. How long is your delivery time?

For sample, about 3-7 days. For mass production, about 10-25 days.

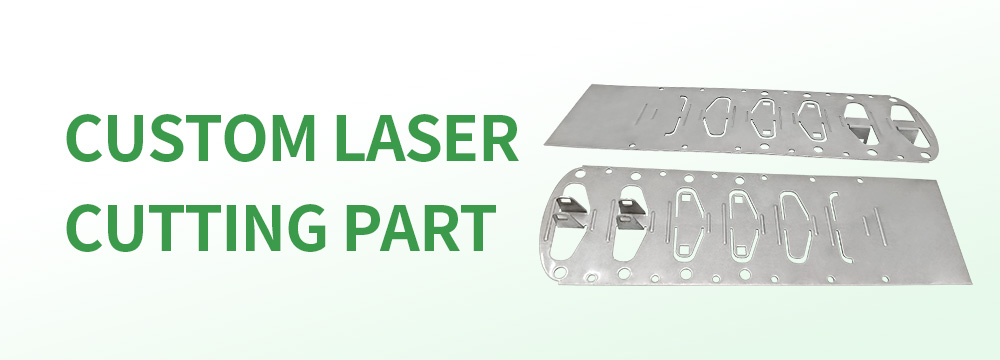

Laser Cutting Stamping Part

In the rapidly evolving fields of electrical engineering and new energy technologies, laser cutting parts have become indispensable components for manufacturing high-precision sheet metal components. This advanced machining technique offers unparalleled advantages in terms of precision, flexibility, and efficiency, making it ideal for applications in electrical enclosures, battery systems, and renewable energy infrastructure.

| Material | Stainless steel, Steel, Copper, Brass, Aluminum, etc. |

| Surface Treatment | Anodizing, Galvanized, Tin-plated, Nickle, Powder Coating, etc. |

| Thichness | 0.1mm-12mm, customized |

| Certification | ISO9001:2015, IATF16949:2016, RoHS |

| Drawing Format | DWG, DXF, STEP, STP, PDF, JPG |

| Application | New Energy, Industry, Electronic, etc. |

Application:

The new energy sector particularly benefits from laser cutting technology:

2. Solar Panel Frames: The technology allows for lightweight yet durable frame designs with minimal material usage, improving overall system efficiency.

Key Applications in Electrical Engineering

1.Enclosures and Cabinets: Laser-cut parts enable the production of complex electrical enclosures with precise cutouts for ventilation, connectors, and mounting points. The technology allows for intricate designs without compromising structural integrity.

2. Busbars and Conductors: The precision of laser cutting ensures clean edges and consistent dimensions for electrical conductors, minimizing resistance and improving current flow efficiency.

The integration of laser cutting technology into electrical and new energy manufacturing processes represents a significant leap forward in component quality and production efficiency. By providing precise, clean-cut parts with minimal material waste, laser cutting technology helps drive innovation across these critical industries. At Wanda-An Precision, we provide laser cutting, stamping, and bending services for your new project.

FAQ:

1. Are you a trading company or a manufacturer?

We are a manufacturer and have been in this field for more than 20 years.

2. How to get a quote?

Please send your 3D drawing(STP, DWG, IGS) to us, and tell us the material, surface treatment, and quantity, then we will quote within 24 hours.

3. What kind of production services do you provide?

Sheet metal fabrication, CNC processing, stamping, laser cutting, bending, welding, assembly, and surface treatment.

4. What kind of surface finish can you provide?

Pulverization, polishing, electroplating, anodizing, hot dip galvanizing, powder coating etc.

5. How long is your delivery time?

For sample, about 3-7 days. For mass production, about 10-25 days.