Shenzhen Wandanan Precision Technology Co., Ltd Info@szwandaancnc.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

Precision Stamping Aluminum Copper Battery Terminal Pole

Battery Terminals: The Current Hub in the New Energy Era:

In new energy, the importance of battery terminals, as the core connecting components of a battery system, is increasingly prominent. Terminals are the key interface between the battery's internal electrodes and the external circuitry. They are typically made of conductive materials such as copper and aluminum, ensuring efficient current transmission and directly affecting battery performance and safety. There are two types of battery terminals: positive terminals and negative terminals.

Structure and Function of Terminals:

Terminals consist of a column, connecting terminals, and a heat dissipation structure, and are connected to the internal electrodes of the battery via welding or mechanical connection. Their design must balance conductivity, mechanical strength, and heat dissipation efficiency. For example, the terminals of square aluminum-cased batteries use a copper-aluminum composite material, maintaining high conductivity while reducing weight and cost. In the Battery Management System (BMS), terminal temperature is a core monitoring parameter; real-time data acquisition helps assess battery status and improve safety.

Applications of Battery Terminals:

Battery terminals are widely used in products such as electric vehicles, smartphones, and laptops. In the electric vehicle sector, the welding quality of the terminals directly affects battery performance and safety. For example, laser welding technology uses high-energy laser beams to form strong welds, reducing the heat-affected zone, preventing material deformation, and significantly improving production efficiency. Furthermore, terminals play a crucial role in energy storage systems. The storage of renewable energy sources such as solar and wind power requires high-efficiency batteries, and terminal batteries are an ideal choice due to their high power density and long lifespan. At Wanda Precision, terminals are mass-produced through machining or sheet metal stamping.

Technological Innovation and Future Trends:

With the expansion of the electric vehicle market, laser welding technology continues to innovate, such as composite welding and annular spot technology, further optimizing welding efficiency and stability. Terminal block design will place greater emphasis on heat dissipation and connection reliability, for example, by using heat dissipation extension structures to improve thermal stability and adapt to high-rate charging and discharging requirements. Intelligent development will also drive advancements in terminal block technology, such as automated and intelligent welding processes, providing solid support for new energy applications.

Product Details:

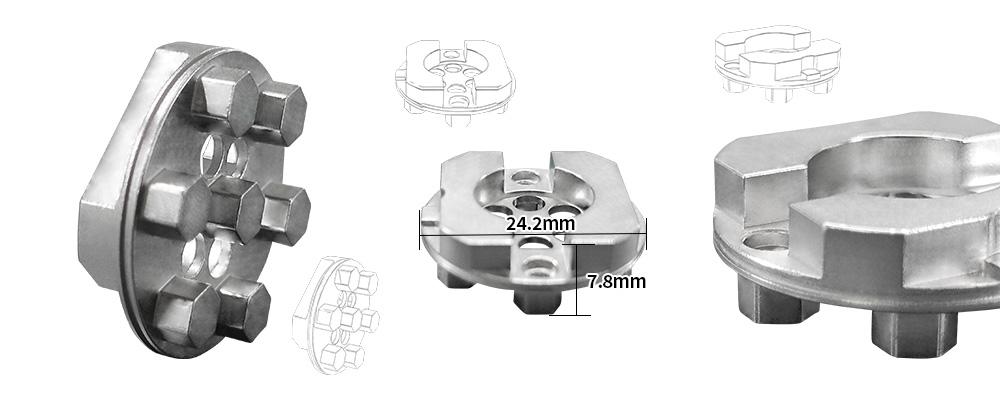

| Model | Battery Negative Terminal Pole |

| Processing | CNC stamping, CNC turning |

| Size | 24.2mm*7.8mm, Customization |

| Sample | 3-7 days |

| Application | Energy storage system, battery packs, new energy vehicle, etc. |

Precision Stamping Aluminum Copper Battery Terminal Pole

Battery Terminals: The Current Hub in the New Energy Era:

In new energy, the importance of battery terminals, as the core connecting components of a battery system, is increasingly prominent. Terminals are the key interface between the battery's internal electrodes and the external circuitry. They are typically made of conductive materials such as copper and aluminum, ensuring efficient current transmission and directly affecting battery performance and safety. There are two types of battery terminals: positive terminals and negative terminals.

Structure and Function of Terminals:

Terminals consist of a column, connecting terminals, and a heat dissipation structure, and are connected to the internal electrodes of the battery via welding or mechanical connection. Their design must balance conductivity, mechanical strength, and heat dissipation efficiency. For example, the terminals of square aluminum-cased batteries use a copper-aluminum composite material, maintaining high conductivity while reducing weight and cost. In the Battery Management System (BMS), terminal temperature is a core monitoring parameter; real-time data acquisition helps assess battery status and improve safety.

Applications of Battery Terminals:

Battery terminals are widely used in products such as electric vehicles, smartphones, and laptops. In the electric vehicle sector, the welding quality of the terminals directly affects battery performance and safety. For example, laser welding technology uses high-energy laser beams to form strong welds, reducing the heat-affected zone, preventing material deformation, and significantly improving production efficiency. Furthermore, terminals play a crucial role in energy storage systems. The storage of renewable energy sources such as solar and wind power requires high-efficiency batteries, and terminal batteries are an ideal choice due to their high power density and long lifespan. At Wanda Precision, terminals are mass-produced through machining or sheet metal stamping.

Technological Innovation and Future Trends:

With the expansion of the electric vehicle market, laser welding technology continues to innovate, such as composite welding and annular spot technology, further optimizing welding efficiency and stability. Terminal block design will place greater emphasis on heat dissipation and connection reliability, for example, by using heat dissipation extension structures to improve thermal stability and adapt to high-rate charging and discharging requirements. Intelligent development will also drive advancements in terminal block technology, such as automated and intelligent welding processes, providing solid support for new energy applications.

Product Details:

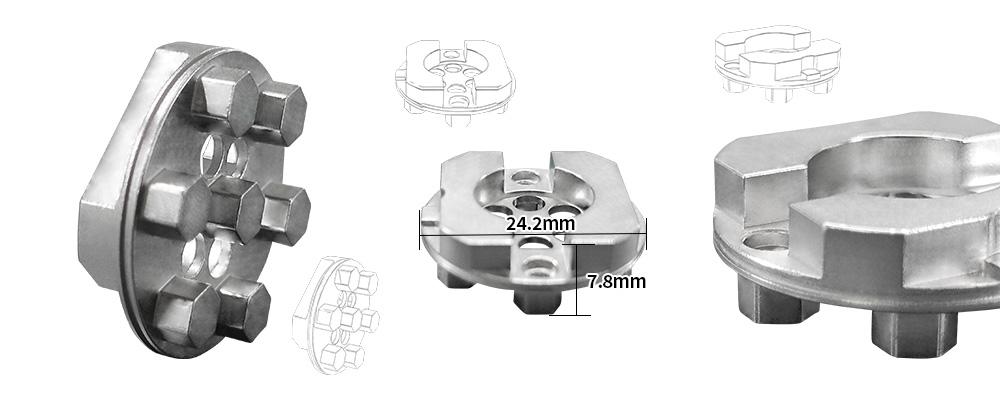

| Model | Battery Negative Terminal Pole |

| Processing | CNC stamping, CNC turning |

| Size | 24.2mm*7.8mm, Customization |

| Sample | 3-7 days |

| Application | Energy storage system, battery packs, new energy vehicle, etc. |